Intro

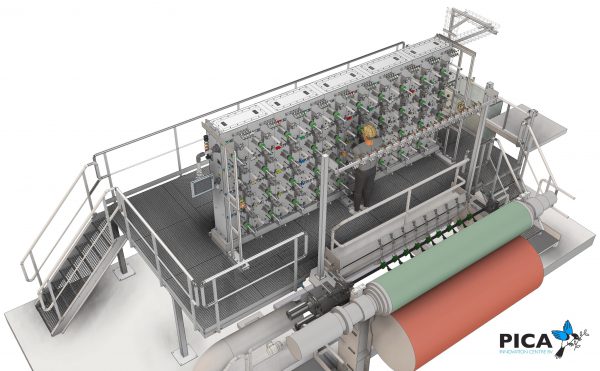

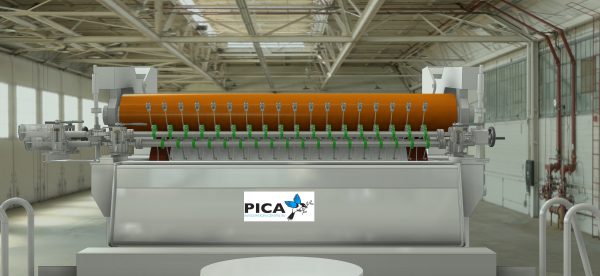

Pica has a number of years , 22 up to now, a global experience in the unwinding and insertion of security threads in banknote paper. The information available is as a full system or as Blueprint (shared Technology) which allows you to manufacture the MUS in your own economy.

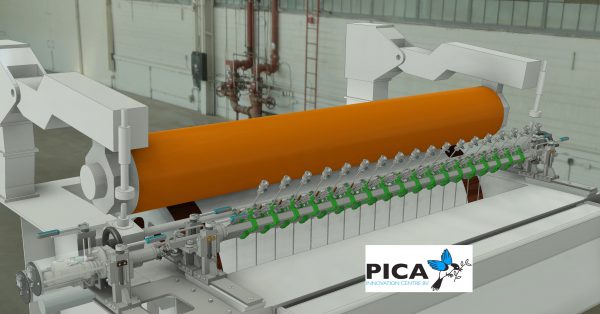

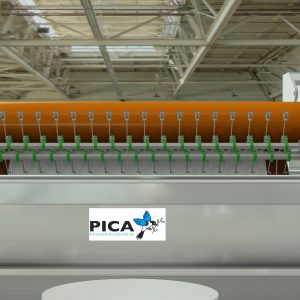

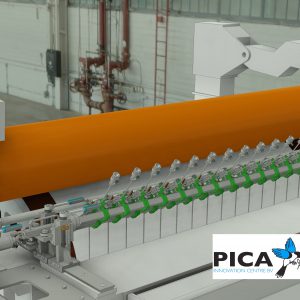

We can offer the latest technology in servo- and automation to bring a number of security threads up to Thread Insertion System or Cylinder Mould, complete with all proces-key-data like bobbin monitoring, automatic splicing, automatic flipping of RSU-Righ Sight Up threads etc…

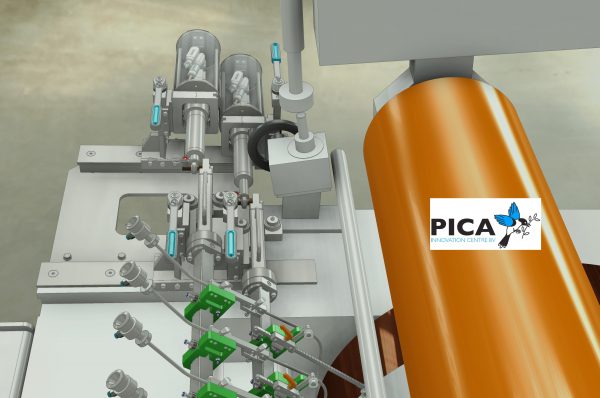

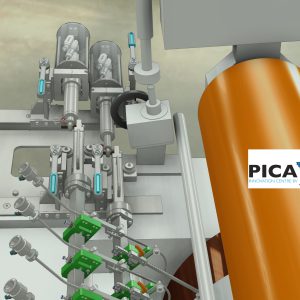

The unwinding heads are fitted with:

- low-mass Dancer with smooth-running guide rollers. (Patented)

- highly dynamic position control.

- Dancer with proportional valve for adjusting the line tension, free adjustable in the HMI-panel;

- adjustable between 20 – 250 cN (by one parameter only)

- other values upon request.

- Accuracy: +/- <5 cN on the set-value

- In comparison with a position control regulated dancer arm with pneumatic cylinder:

- No wear and tear on parts;

- Very constant controlled tension;

- NO STICK-SLIP EFFECT!!!

- A Pilot system is available for demonstration.

All individual Unwinds are having a direct servo-drive on the Bobbinshaft; all types of bobbins can be unwind, from MEFO up to HKV-250 without changing settings or parameters

The Bobbin is directly driven by a high quality servo-motor without reduction. The servo-motor is highly dynamic throughout the whole speed range and has perfect speed regulation over the whole operating range, almost down to stand-still , smooth operation is guaranteed even at very low rpm. Chosen for a servo-motor and –drive means also practically no maintenance and high reliability.

State of the Art Unwind Technology – Constant tension over the whole diameter range at all speeds – A strong reduction in Maintenance-State of the Art Thread Insertion System – Servo-driven Oscillation, programmable against Recipes – Usage of large bobbins – usually 40-80 kms/bobbin at 2-4 mm wide thread – HKV250 – MEFO – HKV200 – significant increase in thread changes – Communication Link between MUS and your PLC based upon an OPC server.

Functions

- Easy and Intuitive Operation Mode, also for new-users

- Status of each unwind by colour

- Digital Tension Setting per Unwind

- Tension to be set individual or as total

- Oscillation Curves

- Sinus

- Block- or Step form

- Custom curves

- Alarm values

- To receive and send recipes.

- Individual unwinder activation and deactivation switches over the field bus

- Dealing with Error and Failures while source can be read in the display.

- Image status unwinder

- Service levels for drive and motor

- This access is dependent on log-in levels in the HMI

- Each Unwind can be addressed to a certain track in the Paper:

- A1….up to A6

- B1….up to B6

- C1….up to C6

- D1….up to D6

- E1…..up to E6

Reference videos:

Euro 20 production: https://youtu.be/vAx1gWFErKI

Euro 50 Production: https://youtu.be/VSE3ubyTH2Y