Year 2015

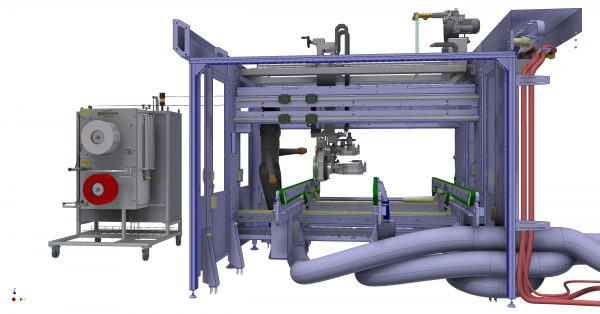

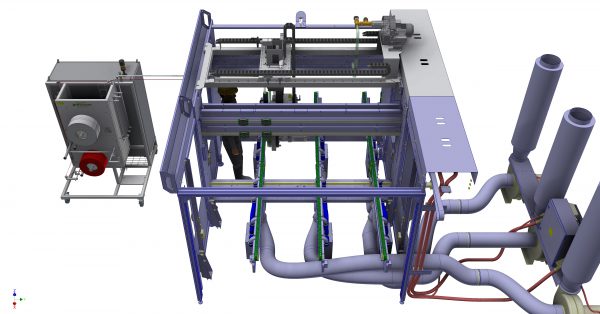

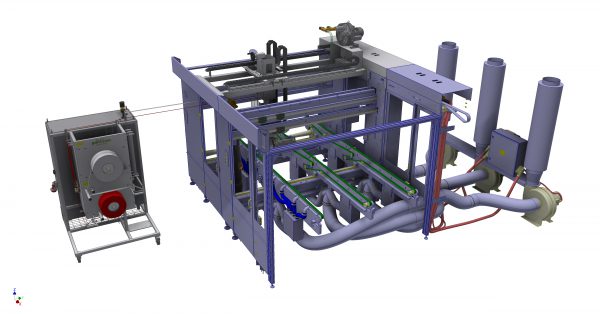

In 2015 we’ve designed our High Speed Taping Machine for a Bobst Masterfold 230.

The HSTA is the Best-in-Class of Taping e-commerce related packaging, extreem Innovative, Reliable, high speed (>200 m/min) on both tearstrip and silicon paper, high commitment of its designers and focussed on one single objective: to be the best in class in the E-Commerce industry

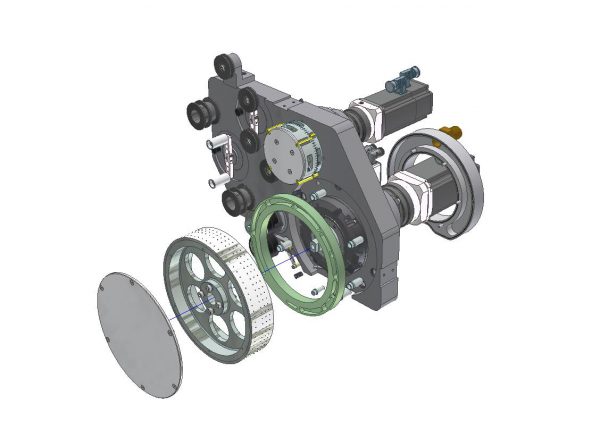

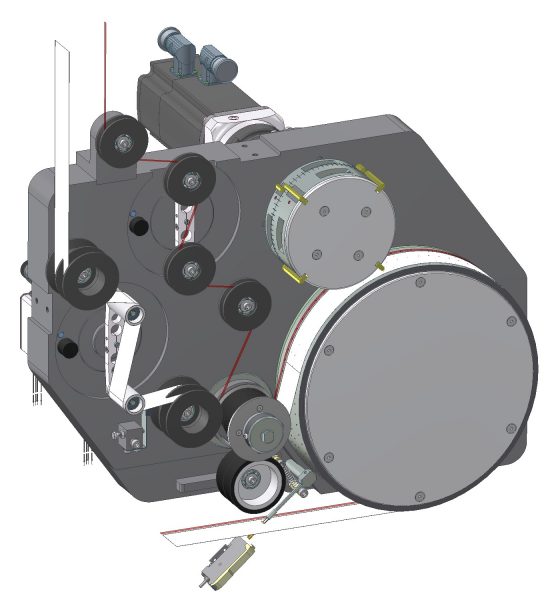

A Unique Servo Driven High Speed Vacuum Wheel Taping System developed to apply Film, Paper, Finger lift Tape as well as Tear Strip Tape

to moving products being conveyed on a folder gluer or similar machine.

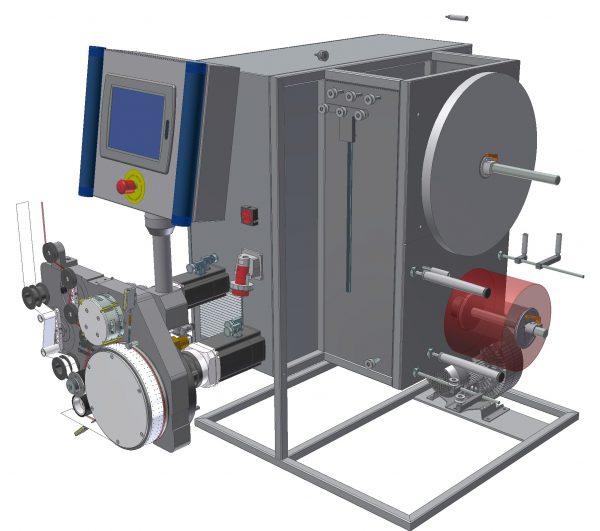

In rspond to sustainability requirements of our customers we’ve recently starten with a system to apply two pieces of Silicon Paper and to eliminate the ‘Plastic’ Tear Tape. One Silicon Strip for Closing and one for Returning

![]()

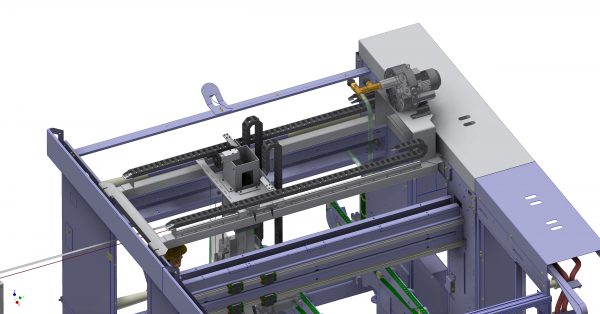

This System applies simultaneously two tapes; both tapes driven by one servo-drive feeding roller and having both the same cut-off length.

We advise not to run “Folded” products through the applicator due to differences in paper-thickness.

A drive roller or -belt underneath the vacuum drum is advised to eliminate differences in speed.

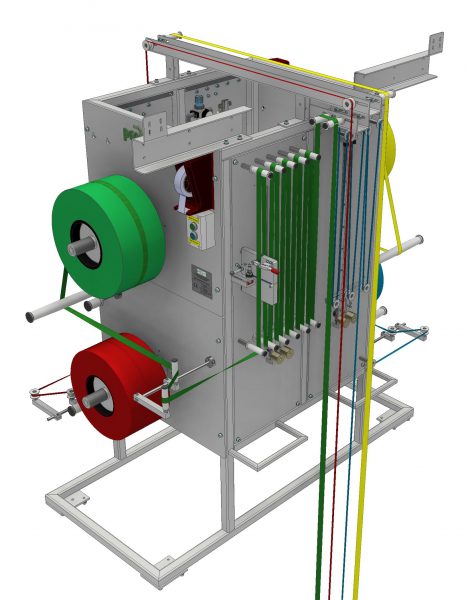

Silicon Paper

- Machine Speed 0-200 m/min>

- Tape Lenght minimum 90mm

- Tape Length maximum 1.500 mm

- Paper width 20-30 mm

- Paper weight 40-70 g/m²

- Reel, Inner core Diameter 6-Inch

- Jumbo Reels, Inner core Diameter 3-Inch

- Jumbo Reels, Outer diameter 350mm (Traverse spooled reels)

Tear Strip Tape

- Machine speed 0-200 m/min

- Tape Length minimum 90 mm

- Tape Length maximum 1.500 mm

- Tape width 4 – 6 mm

- Jumbo Reel, Inner core Diameter 6-Inch (152mm)

- Jumbo Reel, Maximum Outer diameter 350mm